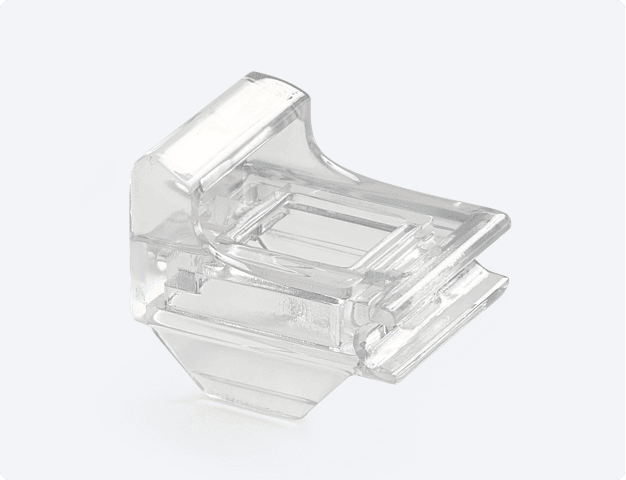

Acryl, commonly known as PMMA or Plexiglas, is derived from the English term “acrylic plastic” and refers to polymethyl methacrylate. It represents one of the early developments in plastic polymer materials, offering excellent transparency, chemical stability, weather resistance, ease of dyeing, and attractive appearance. Due to these properties, acrylic is widely used in the construction industry and can be categorized into cast sheets, extruded sheets, and molded plastics.

Mechanical Properties

Polymethyl methacrylate boasts strong overall mechanical properties, positioning it among the leading general-purpose plastics. Its tensile, bending, and compression strengths surpass those of polyolefins and are higher than those of polystyrene and polyvinyl chloride. While its impact toughness is relatively low, it is slightly better than that of polystyrene. Cast polymerized PMMA sheets, such as those used for aviation-grade Plexiglas, exhibit even higher tensile, bending, and compression strengths, reaching levels comparable to polyamide, polycarbonate, and other engineering plastics.

Typically, the tensile strength of PMMA ranges from 50 to 77 MPA, while its bending strength can reach between 90 and 130 MPA. The upper limits of these performance metrics can match or exceed those of some engineering plastics. However, PMMA has a low elongation at break of only 2%-3%, making it a hard and brittle plastic that is sensitive to gaps and prone to cracking under stress. Unlike polystyrene and ordinary inorganic glass, its fractures tend to be less sharp and uneven. The secondary transition temperature of PMMA is around 40°C, which corresponds to the temperature at which the side methyl groups begin to move; above this temperature, the material’s toughness and ductility improve. It is worth noting that PMMA has low surface hardness and is susceptible to scratching.

The strength of PMMA is influenced by the duration of stress application, decreasing as the duration increases. However, the mechanical properties of oriented PMMA (oriented Plexiglass) improve significantly after tensile orientation, enhancing both strength and notch sensitivity.

In terms of heat resistance, PMMA is not particularly high-performing. Its glass transition temperature is approximately 104°C, but the maximum continuous use temperature varies between 65°C and 95°C depending on working conditions. The heat deflection temperature is about 96°C (at 1.18 MPA), and the Vicat softening point is around 113°C. Heat resistance can be enhanced through copolymerization with acrylate methacrylate or glycol bis-ester acrylate. Cold resistance is also limited, with a brittleness temperature around 9.2°C. PMMA’s thermal stability is moderate, better than that of polyvinyl chloride and polyformaldehyde, but inferior to polyolefin and polystyrene, with a thermal decomposition temperature slightly above 270°C and a flow temperature around 160°C, allowing for a wide range of melt processing temperatures.

The thermal conductivity and specific heat capacity of PMMA are moderate among plastics, measuring 0.19 W/m·K and 1464 J/kg·K, respectively.

Bestellvorgang

Q1: So senden Sie eine Verarbeitungsanfrage?A: Sie können uns über WhatsApp kontaktieren: +86 15323729231 oder E -Mail [email protected].B: Wir unterstützen die Dateiformate der Stufen-/Stl/IGES -Dateiformate. Sie können Ihre Dateien auch an unsere Service -E -Mail senden. Unser System generiert ein Angebot und eine Prozessempfehlungen innerhalb 1 Stunde.

Q2: Stellen Sie Entwurfsoptimierungsvorschläge an?A: Ja! Unser Engineering -Team bietet ein kostenloses DFM (Design für die Herstellung) Rezension, Bereitstellung von Optimierungsvorschlägen zur Verbesserung der Struktur und zur Reduzierung der Kosten.

Preisgestaltung & Lieferung

Q3: Was ist die minimale Bestellmenge (MOQ)?A: Kein MOQ! Wir akzeptieren Bestellungen aus 1 Stück, ob für 3D -Druck- oder CNC -Bearbeitung.

Q4: Was ist im Zitat enthalten?A: Das Angebot deckt die Materialkosten ab, Verarbeitungsgebühren, und grundlegende Oberflächenbehandlung (Z.B., Sandstrahlen). Zusätzliche Prozesse (Z.B., elektroplierend, Anodisierung) wird separat zitiert.

Q5: Was ist die Standardvorlaufzeit??

- CNC -Bearbeitung: 3-5 Tage (bis zu 7 Tage für komplexe Teile)

- 3D Druck: 72 Std.

Technologie & Qualität

Q6: Was ist die Bearbeitungsgenauigkeit??

- CNC -Bearbeitung: Schnelles Prototyping mit einer ± 0,05 mm -Toleranz, 0.1MM Form -Toleranz, und Oberflächenrauheit ra1.6 oder besser.

- 3D Druck:

- Harzteile: ± 0,2 mm

- Nylonteile: ± 0,3 mm

- Kunststoffteile: ± 0,3 mm

- Metallteile: ± 0,3 mm

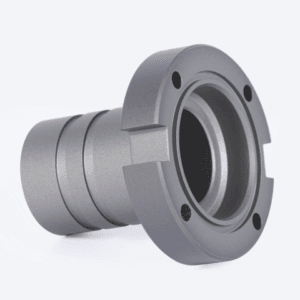

Q7: Welche Materialien unterstützen Sie??✅ CNC -Bearbeitung:

- Aluminiumlegierung: 6061, 7075

- Kupferlegierung: Messing (H59), Rotkupfer (T2)

- Legierungsstahl: 45# Stahl

- Edelstahl: Sus304

- Kunststoff:

- ABS (Weiß, Schwarz)

- Pom (Weiß, Schwarz)

- Bakelit (Schwarz, Orange)

- Acryl (Transparent)

- FR4 Epoxy Board (Grün)

- PA6 Nylon (Weiß)

- Polycarbonat (Transparent)

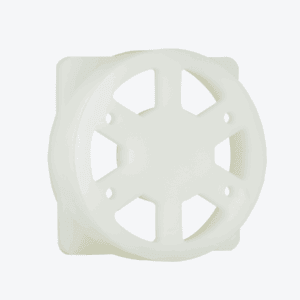

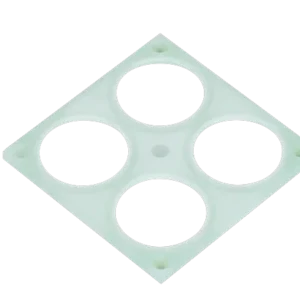

✅ 3D -Druck:

- Harz, Nylon, Technische Kunststoffe, Edelstahl

After-Sales-Service

Q8: Was ist, wenn die Teile den Anforderungen nicht erfüllen??A: Wenn Mängel aufgrund unserer Verarbeitungsprobleme auftreten, Wir garantieren eine kostenlose Wiederaufbereitung.