CNC tournant

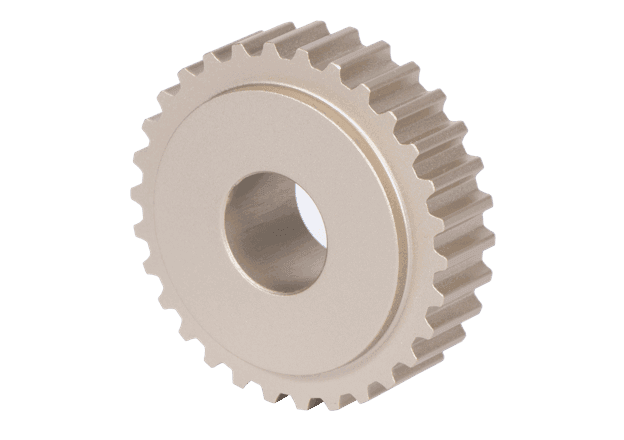

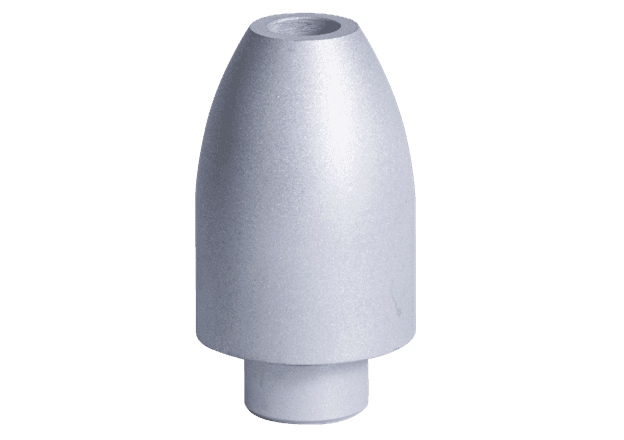

CNC turning is a precision machining process in which a workpiece rotates while a cutting tool removes material, shaping it into cylindrical or conical forms. This method is widely used for manufacturing components such as shafts, pins, and bushings with exceptional accuracy and consistency.

Available Materials for CNC Turning

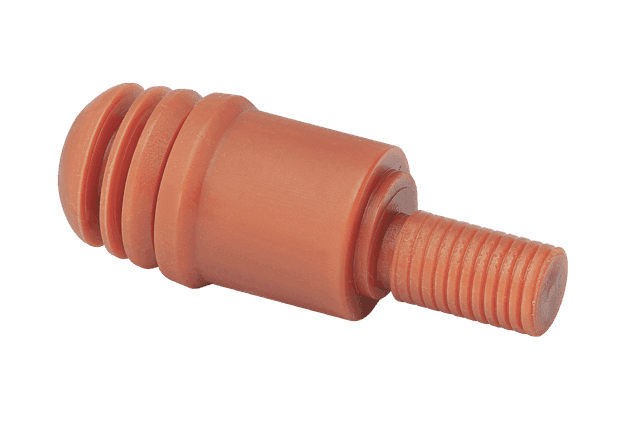

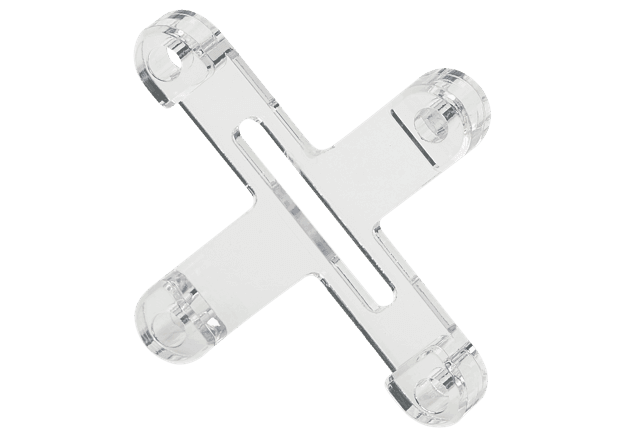

CNC turning is compatible with a wide range of materials, including metals (Aluminium, Acier, Laiton, Cuivre), plastics (Acrylique, Nylon, ABS), composites (Carbon Fiber, Fiberglass), and foams. The choice of material depends on its machinability, which is influenced by factors such as hardness and thermal conductivity. A variety of high-quality materials are available to meet diverse application needs in precision CNC turning.

CNC turning design guidelines

Taille maximale de construction | Ø230, length 300 |

Taille minimale de construction | Ø3 |

Recommend Size | 6-230MM |

Recommend Accuracy | ±0.05mm |

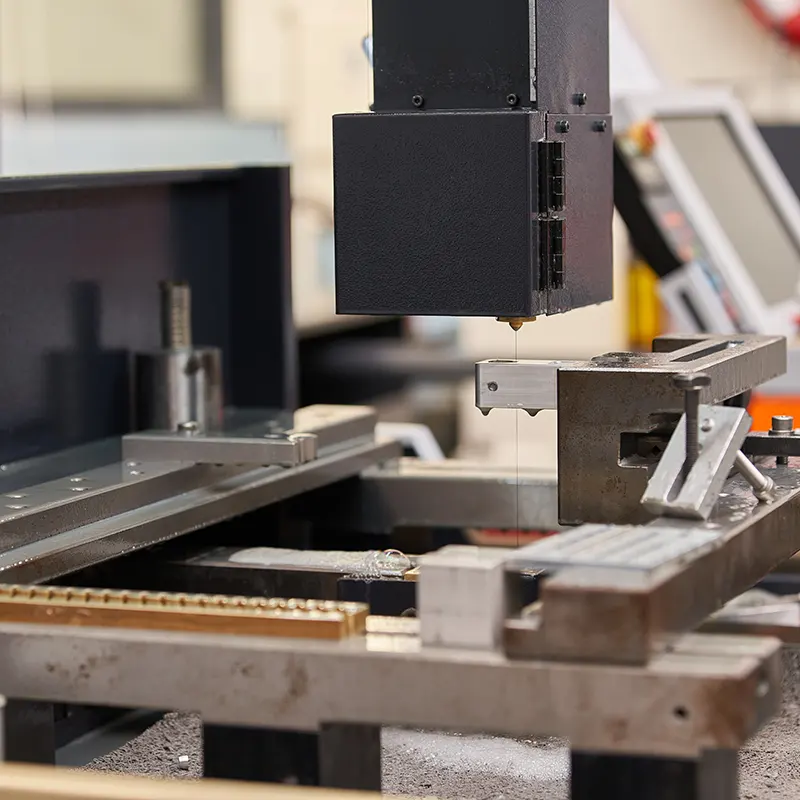

How Does CNC Turning Machine Work

A CNC turning machine functions by spinning a workpiece around its axis while a cutting tool follows a programmed path to precisely remove material, shaping the component with high accuracy and efficiency.