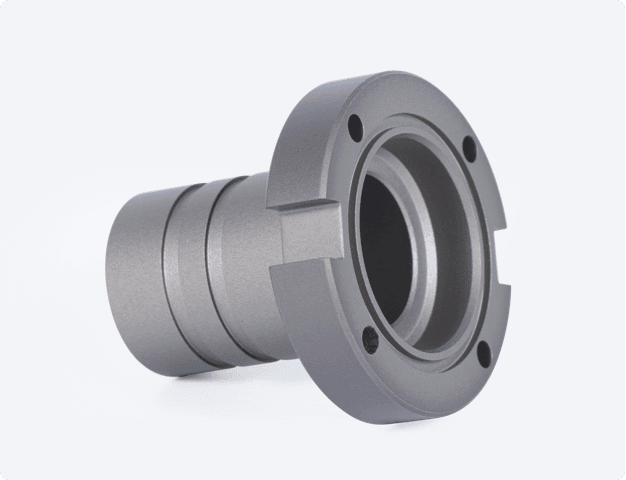

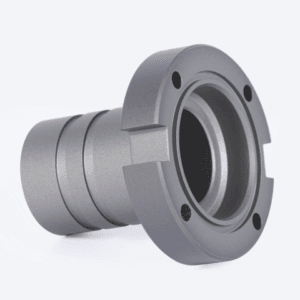

6061 (T6) aluminum alloy is a high-quality aluminum product created through a heat treatment and pre-stretching process. This alloy falls under the category of heat-treatable strengthening alloys, offering excellent formability, weldability, and machinability. It possesses medium strength and retains good operability after annealing. The primary alloying elements in 6061 aluminum are magnesium and silicon, which combine to form the Mg2Si phase. The addition of manganese and chromium can help neutralize the negative effects of iron, while small amounts of copper or zinc can enhance the alloy’s strength without significantly compromising its corrosion resistance. Copper can also mitigate the adverse effects of titanium and iron on electrical conductivity. Furthermore, zirconium or titanium can refine the grain structure and control recrystallization, while lead and bismuth may be added to improve machinability. The dissolution of Mg2Si in aluminum provides the alloy with artificial aging hardening capabilities.

Mechanical Properties:

Tensile Strength (σb): ≥ 290 MPa

Elongation Stress (σp0.2): ≥ 240 MPa

Elongation Rate: ≥ 10%

Note: These mechanical properties pertain to seamless rods with a specimen size of diameter ≥ 70 mm.

Heat Treatment Process:

Rapid Annealing: Heating temperature of 350-410°C; holding time varies from 30 to 120 minutes depending on the effective thickness of the material; cooled by air or water.

High-Temperature Annealing: Heating temperature of 350-500°C; for finished products with a thickness of ≥ 6 mm, holding time is 10-30 minutes; for thickness less than 6 mm, heat through air cooling.

Low-Temperature Annealing: Heating temperature of 150-250°C; holding time is 2-3 hours; cooled by air or water.

Homogenization: Conducted at 570°C with a holding time of 7 hours, followed by air cooling.

Additional Information:

The density of 6061 aluminum alloy is approximately 2800 kg/m³.

6061 aluminum alloy is widely used in various applications, including structural components, automotive parts, and aerospace applications, due to its favorable combination of strength and workability.

Order Process

Q1: How to submit a processing request?A: You can contact us via WhatsApp: +86 15323729231 or email [email protected].B: We support STEP/STL/IGES file formats. You can also send your files to our service email. Our system will generate a quote and process recommendations within 1 hour.

Q2: Do you provide design optimization suggestions?A: Yes! Our engineering team offers a free DFM (Design for Manufacturability) review, providing optimization suggestions to improve structure and reduce costs.

Pricing & Delivery

Q3: What is the Minimum Order Quantity (MOQ)?A: No MOQ! We accept orders starting from 1 piece, whether for 3D printing or CNC machining.

Q4: What is included in the quotation?A: The quote covers material costs, processing fees, and basic surface treatment (e.g., sandblasting). Additional processes (e.g., electroplating, anodizing) will be quoted separately.

Q5: What is the standard lead time?

- CNC Machining: 3-5 days (up to 7 days for complex parts)

- 3D Printing: 72 hours

Technology & Quality

Q6: What is the machining accuracy?

- CNC Machining: Fast prototyping with a ±0.05mm tolerance, 0.1mm form tolerance, and surface roughness Ra1.6 or better.

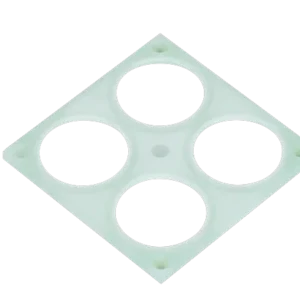

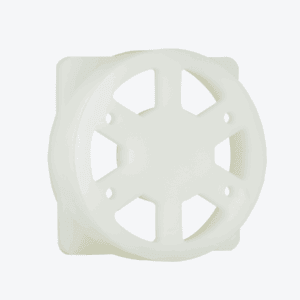

- 3D Printing:

- Resin parts: ±0.2mm

- Nylon parts: ±0.3mm

- Plastic parts: ±0.3mm

- Metal parts: ±0.3mm

Q7: What materials do you support?✅ CNC Machining:

- Aluminum Alloy: 6061, 7075

- Copper Alloy: Brass (H59), Red Copper (T2)

- Alloy Steel: 45# Steel

- Stainless Steel: SUS304

- Plastics:

- ABS (White, Black)

- POM (White, Black)

- Bakelite (Black, Orange)

- Acrylic (Transparent)

- FR4 Epoxy Board (Green)

- PA6 Nylon (White)

- Polycarbonate (Transparent)

✅ 3D Printing:

- Resin, Nylon, Engineering Plastics, Stainless Steel

After-Sales Service

Q8: What if the parts do not meet the requirements?A: If defects occur due to our processing issues, we guarantee free remanufacturing.