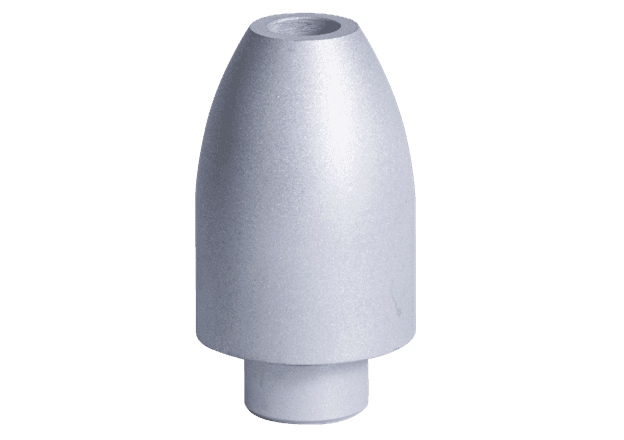

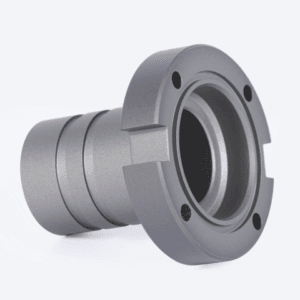

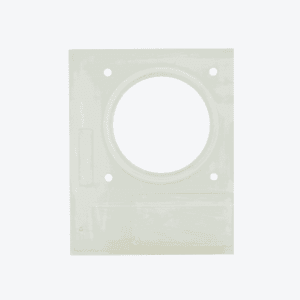

Aluminum 7075 CNC Machining

7075 aluminum alloy is a cold-treated forging alloy known for its high strength, significantly surpassing that of soft steel. It is one of the strongest commercial alloys available and features a dense structure with excellent corrosion resistance, making it ideal for aviation and marine applications. The alloy exhibits general corrosion resistance, good mechanical properties, and favorable anodic reaction characteristics. Its fine grain structure enhances depth drilling performance and improves tool wear resistance.

Mechanical Properties

Tensile Strength (σb): ≥ 560 MPa

Elongation Stress (σp0.2): ≥ 450 MPa

Elongation Rate (%): ≥ 10

Note: These mechanical properties apply to seamless rods with a specimen size of diameter ≥ 70 mm.

Heat Treatment

7075 aluminum exhibits improved forming properties in the annealed and newly quenched states, with a significant strengthening effect from heat treatment. However, the heat treatment process must be strictly controlled. While the corrosion resistance of 7075 aluminum is relatively poor, it can be effectively protected through cladding with pure aluminum. Welding can lead to crack formation, but with specialized techniques, it can be welded and riveted successfully.

This alloy is widely used in applications that require high strength and weight efficiency, such as aerospace components, military vehicles, and high-stress structural applications.

Order Process

Q1: How to submit a processing request?A: You can contact us via WhatsApp: +86 15323729231 or email [email protected].B: We support STEP/STL/IGES file formats. You can also send your files to our service email. Our system will generate a quote and process recommendations within 1 hour.

Q2: Do you provide design optimization suggestions?A: Yes! Our engineering team offers a free DFM (Design for Manufacturability) review, providing optimization suggestions to improve structure and reduce costs.

Pricing & Delivery

Q3: What is the Minimum Order Quantity (MOQ)?A: No MOQ! We accept orders starting from 1 piece, whether for 3D printing or CNC machining.

Q4: What is included in the quotation?A: The quote covers material costs, processing fees, and basic surface treatment (e.g., sandblasting). Additional processes (e.g., electroplating, anodizing) will be quoted separately.

Q5: What is the standard lead time?

- CNC Machining: 3-5 days (up to 7 days for complex parts)

- 3D Printing: 72 hours

Technology & Quality

Q6: What is the machining accuracy?

- CNC Machining: Fast prototyping with a ±0.05mm tolerance, 0.1mm form tolerance, and surface roughness Ra1.6 or better.

- 3D Printing:

- Resin parts: ±0.2mm

- Nylon parts: ±0.3mm

- Plastic parts: ±0.3mm

- Metal parts: ±0.3mm

Q7: What materials do you support?✅ CNC Machining:

- Aluminum Alloy: 6061, 7075

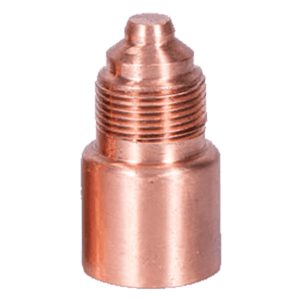

- Copper Alloy: Brass (H59), Red Copper (T2)

- Alloy Steel: 45# Steel

- Stainless Steel: SUS304

- Plastics:

- ABS (White, Black)

- POM (White, Black)

- Bakelite (Black, Orange)

- Acrylic (Transparent)

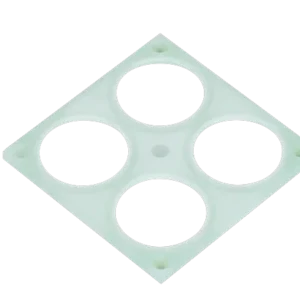

- FR4 Epoxy Board (Green)

- PA6 Nylon (White)

- Polycarbonate (Transparent)

✅ 3D Printing:

- Resin, Nylon, Engineering Plastics, Stainless Steel

After-Sales Service

Q8: What if the parts do not meet the requirements?A: If defects occur due to our processing issues, we guarantee free remanufacturing.