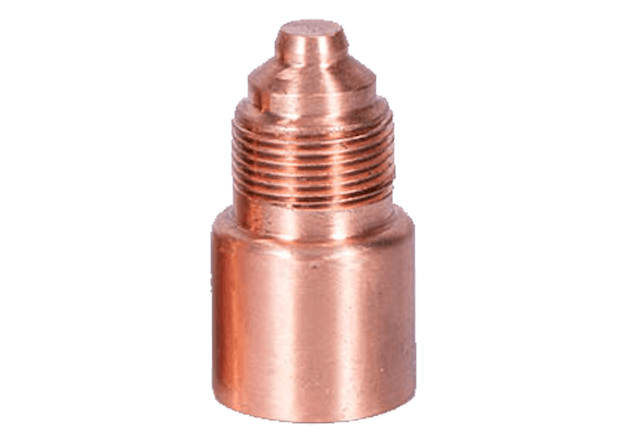

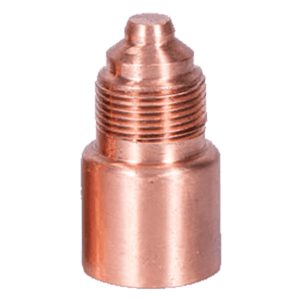

Copper – T2 CNC Machining

T2 copper, also known as purple copper, is a copper-silver alloy with a copper content greater than 99.9%, and it does not have specific requirements for phosphorus content. This alloy exhibits excellent electrical conductivity, with a minimum of 56 Ms/m and a resistance of ≤ 0.0178 x 10⁻⁶ Ω·m.

Mechanical Properties

Specimen Size: Thickness ≥ 0.2 mm

Tensile Strength (σb): ≥ 195 MPa

Vickers Hardness: ≤ 70 HV

Mechanical Properties Remarks: The tensile mechanical properties are measured at room temperature for strips.

Heat Treatment

Heat Processing Temperature: 900 – 1050°C

Annealing Temperature: 500 – 700°C

Recrystallization Start Temperature for Cold Work-Hardened Copper: 200 – 300°C

T2 copper is widely used in applications requiring high electrical conductivity and good mechanical properties, making it suitable for various CNC machining processes.

Order Process

Q1: How to submit a processing request?A: You can contact us via WhatsApp: +86 15323729231 or email [email protected].B: We support STEP/STL/IGES file formats. You can also send your files to our service email. Our system will generate a quote and process recommendations within 1 hour.

Q2: Do you provide design optimization suggestions?A: Yes! Our engineering team offers a free DFM (Design for Manufacturability) review, providing optimization suggestions to improve structure and reduce costs.

Pricing & Delivery

Q3: What is the Minimum Order Quantity (MOQ)?A: No MOQ! We accept orders starting from 1 piece, whether for 3D printing or CNC machining.

Q4: What is included in the quotation?A: The quote covers material costs, processing fees, and basic surface treatment (e.g., sandblasting). Additional processes (e.g., electroplating, anodizing) will be quoted separately.

Q5: What is the standard lead time?

- CNC Machining: 3-5 days (up to 7 days for complex parts)

- 3D Printing: 72 hours

Technology & Quality

Q6: What is the machining accuracy?

- CNC Machining: Fast prototyping with a ±0.05mm tolerance, 0.1mm form tolerance, and surface roughness Ra1.6 or better.

- 3D Printing:

- Resin parts: ±0.2mm

- Nylon parts: ±0.3mm

- Plastic parts: ±0.3mm

- Metal parts: ±0.3mm

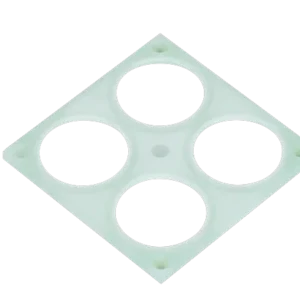

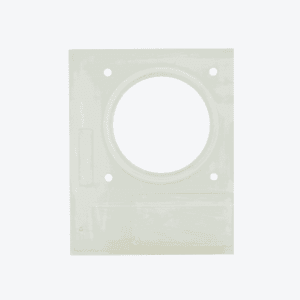

Q7: What materials do you support?✅ CNC Machining:

- Aluminum Alloy: 6061, 7075

- Copper Alloy: Brass (H59), Red Copper (T2)

- Alloy Steel: 45# Steel

- Stainless Steel: SUS304

- Plastics:

- ABS (White, Black)

- POM (White, Black)

- Bakelite (Black, Orange)

- Acrylic (Transparent)

- FR4 Epoxy Board (Green)

- PA6 Nylon (White)

- Polycarbonate (Transparent)

✅ 3D Printing:

- Resin, Nylon, Engineering Plastics, Stainless Steel

After-Sales Service

Q8: What if the parts do not meet the requirements?A: If defects occur due to our processing issues, we guarantee free remanufacturing.