FR-4 is the code name for a flame-resistant material grade, indicating that the resin material must be self-extinguishing after burning. Most FR-4 materials are composite materials made from Tera-Function epoxy resin combined with fillers and glass fibers. Depending on the application, the industry commonly refers to FR-4 epoxy glass cloth laminate as FR-4 epoxy glass cloth, insulation board, epoxy board, brominated epoxy resin board, FR-4 glass fiber board, FR-4 reinforcement board, FPC reinforcement board, flexible circuit board reinforcement board, FR-4 epoxy resin board, flame retardant insulation board, FR-4 laminate, and various other designations, including optical boards and drilling pads for circuit boards.

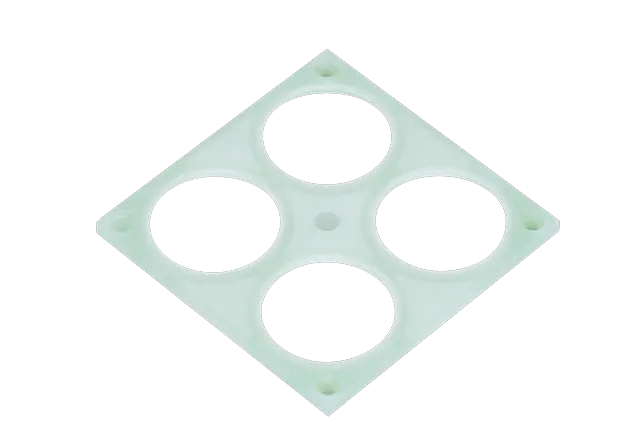

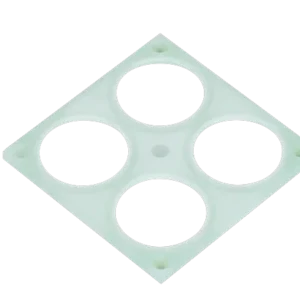

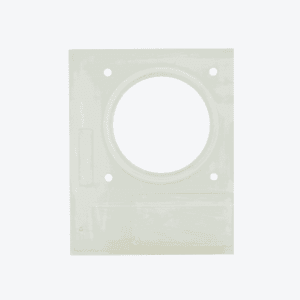

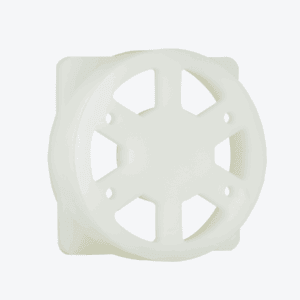

Key technical features and applications include stable electrical insulation properties, good flatness, a smooth surface without pits, and standard thickness tolerances. These characteristics make it suitable for high-performance electronic insulation products such as FPC reinforcement boards, PCB drilling mats, glass fiber substrates, carbon film printed glass fiber boards, precision star gears (wafer grinding), precision test plates, electrical equipment insulation spacers, transformer insulation boards, motor insulation parts, grinding gears, and electronic switch insulation boards.

Mechanical properties include:

Vertical bending strength A: Normal conditions E-1/150, 150±5℃ ≥ 340 MPa

Parallel laminar impact strength (simply supported beam method): ≥ 230 KJ/m

Insulation resistance after water immersion (D-24/23): ≥ 5.0×10^8 Ω

Vertical layer electrical strength (in 90 ± 2℃ transformer oil, plate thickness of 1mm): ≥ 14.2 MV/m

Parallel layer breakdown voltage (in 90 ± 2℃ transformer oil): ≥ 40 KV

Relative dielectric constant (50Hz): ≤ 5.5

Relative permittivity (1MHz): ≤ 5.5

Dielectric loss factor (50Hz): ≤ 0.04

Dielectric loss factor (1MHz): ≤ 0.04

Water absorption (D-24/23, plate thickness 1.6mm): ≤ 19 mg

Density: 1.70-1.90 g/cm³

Flammability: FV0

Heat treatment: Melting point of FR-4 process press board is 203℃

Additionally, it exhibits high chemical resistance, a low loss coefficient (Df 0.0025), a stable and low dielectric constant (Dk 2.35), and is classified as a thermoplastic material.

Order Process

Q1: How to submit a processing request?A: You can contact us via WhatsApp: +86 15323729231 or email [email protected].B: We support STEP/STL/IGES file formats. You can also send your files to our service email. Our system will generate a quote and process recommendations within 1 hour.

Q2: Do you provide design optimization suggestions?A: Yes! Our engineering team offers a free DFM (Design for Manufacturability) review, providing optimization suggestions to improve structure and reduce costs.

Pricing & Delivery

Q3: What is the Minimum Order Quantity (MOQ)?A: No MOQ! We accept orders starting from 1 piece, whether for 3D printing or CNC machining.

Q4: What is included in the quotation?A: The quote covers material costs, processing fees, and basic surface treatment (e.g., sandblasting). Additional processes (e.g., electroplating, anodizing) will be quoted separately.

Q5: What is the standard lead time?

- CNC Machining: 3-5 days (up to 7 days for complex parts)

- 3D Printing: 72 hours

Technology & Quality

Q6: What is the machining accuracy?

- CNC Machining: Fast prototyping with a ±0.05mm tolerance, 0.1mm form tolerance, and surface roughness Ra1.6 or better.

- 3D Printing:

- Resin parts: ±0.2mm

- Nylon parts: ±0.3mm

- Plastic parts: ±0.3mm

- Metal parts: ±0.3mm

Q7: What materials do you support?✅ CNC Machining:

- Aluminum Alloy: 6061, 7075

- Copper Alloy: Brass (H59), Red Copper (T2)

- Alloy Steel: 45# Steel

- Stainless Steel: SUS304

- Plastics:

- ABS (White, Black)

- POM (White, Black)

- Bakelite (Black, Orange)

- Acrylic (Transparent)

- FR4 Epoxy Board (Green)

- PA6 Nylon (White)

- Polycarbonate (Transparent)

✅ 3D Printing:

- Resin, Nylon, Engineering Plastics, Stainless Steel

After-Sales Service

Q8: What if the parts do not meet the requirements?A: If defects occur due to our processing issues, we guarantee free remanufacturing.