Nylon 6, also known as PA6 or polyamide 6, is a polymer compound. On October 27, 2017, the World Health Organization’s International Agency for Research on Cancer included Nylon 6 in its preliminary list of Group 3 carcinogens.

Mechanical Properties

The chemical and physical properties of Nylon 6 are quite similar to those of Nylon 66. However, Nylon 6 has a lower melting point and a broader processing temperature range. It exhibits better impact resistance and dissolution resistance compared to Nylon 66, but it is also more hygroscopic. Because moisture absorption can significantly affect the quality characteristics of plastic parts, it is crucial to consider this factor when designing products using Nylon 6.

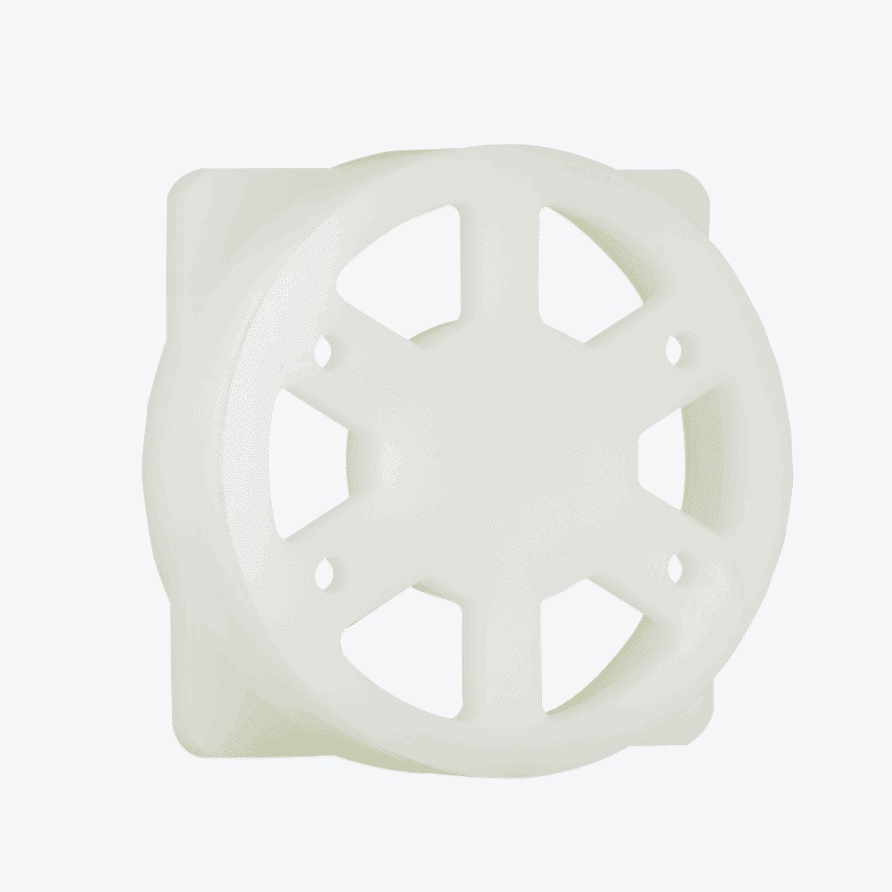

To enhance the mechanical properties of Nylon 6, various modifiers are often added. Glass fiber is the most common additive, while synthetic rubbers like EPDM and SBR may also be included to improve impact resistance. For unmodified Nylon 6, the shrinkage rate typically ranges from 1% to 1.5%. The incorporation of glass fiber can reduce the shrinkage to about 0.3%, although it may be slightly higher in the direction perpendicular to the processing flow. The shrinkage of molded assemblies is primarily influenced by the material’s crystallinity and moisture absorption. Actual shrinkage can also vary based on part design, wall thickness, and other processing parameters.

Nylon 6 Injection Molding Drying Treatment

Due to its high moisture absorption, special attention must be given to drying Nylon 6 before processing. If the material is supplied in a moisture-proof package, it should be kept airtight. If the humidity exceeds 0.2%, it is recommended to dry the material in hot air at temperatures above 80°C for 16 hours. If the material has been exposed to air for more than 8 hours, vacuum drying at 105°C for over 8 hours is advisable.

Order Process

Q1: How to submit a processing request?A: You can contact us via WhatsApp: +86 15323729231 or email [email protected].B: We support STEP/STL/IGES file formats. You can also send your files to our service email. Our system will generate a quote and process recommendations within 1 hour.

Q2: Do you provide design optimization suggestions?A: Yes! Our engineering team offers a free DFM (Design for Manufacturability) review, providing optimization suggestions to improve structure and reduce costs.

Pricing & Delivery

Q3: What is the Minimum Order Quantity (MOQ)?A: No MOQ! We accept orders starting from 1 piece, whether for 3D printing or CNC machining.

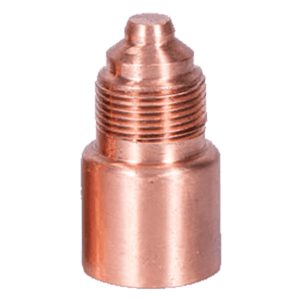

Q4: What is included in the quotation?A: The quote covers material costs, processing fees, and basic surface treatment (e.g., sandblasting). Additional processes (e.g., electroplating, anodizing) will be quoted separately.

Q5: What is the standard lead time?

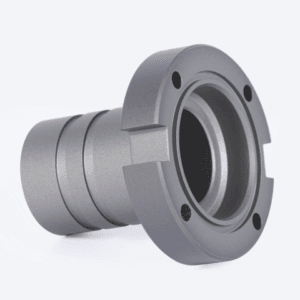

- CNC Machining: 3-5 days (up to 7 days for complex parts)

- 3D Printing: 72 hours

Technology & Quality

Q6: What is the machining accuracy?

- CNC Machining: Fast prototyping with a ±0.05mm tolerance, 0.1mm form tolerance, and surface roughness Ra1.6 or better.

- 3D Printing:

- Resin parts: ±0.2mm

- Nylon parts: ±0.3mm

- Plastic parts: ±0.3mm

- Metal parts: ±0.3mm

Q7: What materials do you support?✅ CNC Machining:

- Aluminum Alloy: 6061, 7075

- Copper Alloy: Brass (H59), Red Copper (T2)

- Alloy Steel: 45# Steel

- Stainless Steel: SUS304

- Plastics:

- ABS (White, Black)

- POM (White, Black)

- Bakelite (Black, Orange)

- Acrylic (Transparent)

- FR4 Epoxy Board (Green)

- PA6 Nylon (White)

- Polycarbonate (Transparent)

✅ 3D Printing:

- Resin, Nylon, Engineering Plastics, Stainless Steel

After-Sales Service

Q8: What if the parts do not meet the requirements?A: If defects occur due to our processing issues, we guarantee free remanufacturing.