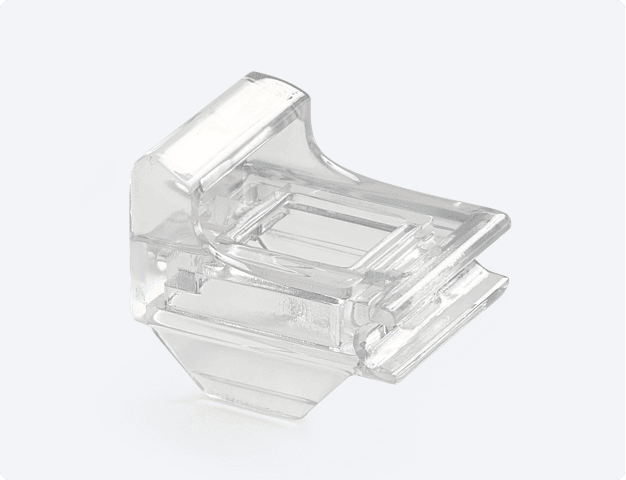

Acrylic, commonly known as PMMA or Plexiglas, is derived from the English term “acrylic plastic” and refers to polymethyl methacrylate. It represents one of the early developments in plastic polymer materials, offering excellent transparency, chemical stability, weather resistance, ease of dyeing, and attractive appearance. Due to these properties, acrylic is widely used in the construction industry and can be categorized into cast sheets, extruded sheets, and molded plastics.

Mechanical Properties

Polymethyl methacrylate boasts strong overall mechanical properties, positioning it among the leading general-purpose plastics. Its tensile, bending, and compression strengths surpass those of polyolefins and are higher than those of polystyrene and polyvinyl chloride. While its impact toughness is relatively low, it is slightly better than that of polystyrene. Cast polymerized PMMA sheets, such as those used for aviation-grade Plexiglas, exhibit even higher tensile, bending, and compression strengths, reaching levels comparable to polyamide, polycarbonate, and other engineering plastics.

Typically, the tensile strength of PMMA ranges from 50 to 77 MPa, while its bending strength can reach between 90 and 130 MPa. The upper limits of these performance metrics can match or exceed those of some engineering plastics. However, PMMA has a low elongation at break of only 2%-3%, making it a hard and brittle plastic that is sensitive to gaps and prone to cracking under stress. Unlike polystyrene and ordinary inorganic glass, its fractures tend to be less sharp and uneven. The secondary transition temperature of PMMA is around 40°C, which corresponds to the temperature at which the side methyl groups begin to move; above this temperature, the material’s toughness and ductility improve. It is worth noting that PMMA has low surface hardness and is susceptible to scratching.

The strength of PMMA is influenced by the duration of stress application, decreasing as the duration increases. However, the mechanical properties of oriented PMMA (oriented Plexiglass) improve significantly after tensile orientation, enhancing both strength and notch sensitivity.

In terms of heat resistance, PMMA is not particularly high-performing. Its glass transition temperature is approximately 104°C, but the maximum continuous use temperature varies between 65°C and 95°C depending on working conditions. The heat deflection temperature is about 96°C (at 1.18 MPa), and the Vicat softening point is around 113°C. Heat resistance can be enhanced through copolymerization with acrylate methacrylate or glycol bis-ester acrylate. Cold resistance is also limited, with a brittleness temperature around 9.2°C. PMMA’s thermal stability is moderate, better than that of polyvinyl chloride and polyformaldehyde, but inferior to polyolefin and polystyrene, with a thermal decomposition temperature slightly above 270°C and a flow temperature around 160°C, allowing for a wide range of melt processing temperatures.

The thermal conductivity and specific heat capacity of PMMA are moderate among plastics, measuring 0.19 W/m·K and 1464 J/kg·K, respectively.

Order Process

Q1: How to submit a processing request?A: You can contact us via WhatsApp: +86 15323729231 or email [email protected].B: We support STEP/STL/IGES file formats. You can also send your files to our service email. Our system will generate a quote and process recommendations within 1 hour.

Q2: Do you provide design optimization suggestions?A: Yes! Our engineering team offers a free DFM (Design for Manufacturability) review, providing optimization suggestions to improve structure and reduce costs.

Pricing & Delivery

Q3: What is the Minimum Order Quantity (MOQ)?A: No MOQ! We accept orders starting from 1 piece, whether for 3D printing or CNC machining.

Q4: What is included in the quotation?A: The quote covers material costs, processing fees, and basic surface treatment (e.g., sandblasting). Additional processes (e.g., electroplating, anodizing) will be quoted separately.

Q5: What is the standard lead time?

- CNC Machining: 3-5 days (up to 7 days for complex parts)

- 3D Printing: 72 hours

Technology & Quality

Q6: What is the machining accuracy?

- CNC Machining: Fast prototyping with a ±0.05mm tolerance, 0.1mm form tolerance, and surface roughness Ra1.6 or better.

- 3D Printing:

- Resin parts: ±0.2mm

- Nylon parts: ±0.3mm

- Plastic parts: ±0.3mm

- Metal parts: ±0.3mm

Q7: What materials do you support?✅ CNC Machining:

- Aluminum Alloy: 6061, 7075

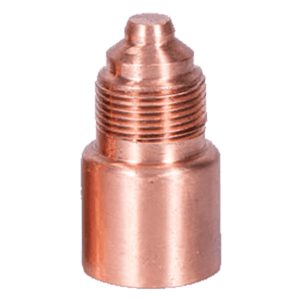

- Copper Alloy: Brass (H59), Red Copper (T2)

- Alloy Steel: 45# Steel

- Stainless Steel: SUS304

- Plastics:

- ABS (White, Black)

- POM (White, Black)

- Bakelite (Black, Orange)

- Acrylic (Transparent)

- FR4 Epoxy Board (Green)

- PA6 Nylon (White)

- Polycarbonate (Transparent)

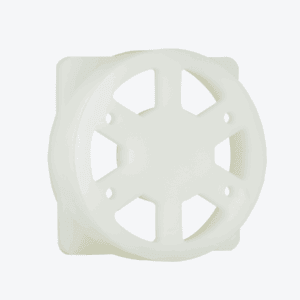

✅ 3D Printing:

- Resin, Nylon, Engineering Plastics, Stainless Steel

After-Sales Service

Q8: What if the parts do not meet the requirements?A: If defects occur due to our processing issues, we guarantee free remanufacturing.