Polycarbonate (commonly abbreviated as PC) is a polymer that contains carbonate groups in its molecular chain. It can be categorized into different types based on the structure of the ester group, including aliphatic, aromatic, and aliphatic-aromatic polycarbonates. Among these, only aromatic polycarbonates are produced industrially, as aliphatic and aliphatic-aromatic polycarbonates exhibit lower mechanical properties, which limits their application in engineering plastics. Due to its unique structural characteristics, polycarbonate has emerged as the fastest-growing general engineering plastic among the five major engineering plastics.

Mechanical Properties:

Density: 1.18-1.22 g/cm³

Linear Expansion: 3.8×10⁻⁵ cm/°C

Heat Deflection Temperature: 135°C

Low Temperature Resistance: -45°C

Polycarbonate is colorless and transparent, with excellent heat resistance, impact resistance, and flame retardant properties (BI grade). It maintains good mechanical properties within common usage temperatures. While its performance is comparable to that of polymethyl methacrylate (PMMA), polycarbonate offers superior impact resistance, a high refractive index, and good processing capabilities. Additionally, it achieves UL94 V-2 flame retardant performance without the need for additives. However, PMMA is generally less expensive and can be produced in larger quantities through continuous polymerization.

In terms of abrasion resistance, polycarbonate outperforms ABS materials, but when compared to most plastic materials, its abrasion resistance is relatively moderate, placing it in the middle to lower range. Consequently, polycarbonate components intended for wear applications may require special surface treatments to enhance durability.

Order Process

Q1: How to submit a processing request?A: You can contact us via WhatsApp: +86 15323729231 or email [email protected].B: We support STEP/STL/IGES file formats. You can also send your files to our service email. Our system will generate a quote and process recommendations within 1 hour.

Q2: Do you provide design optimization suggestions?A: Yes! Our engineering team offers a free DFM (Design for Manufacturability) review, providing optimization suggestions to improve structure and reduce costs.

Pricing & Delivery

Q3: What is the Minimum Order Quantity (MOQ)?A: No MOQ! We accept orders starting from 1 piece, whether for 3D printing or CNC machining.

Q4: What is included in the quotation?A: The quote covers material costs, processing fees, and basic surface treatment (e.g., sandblasting). Additional processes (e.g., electroplating, anodizing) will be quoted separately.

Q5: What is the standard lead time?

- CNC Machining: 3-5 days (up to 7 days for complex parts)

- 3D Printing: 72 hours

Technology & Quality

Q6: What is the machining accuracy?

- CNC Machining: Fast prototyping with a ±0.05mm tolerance, 0.1mm form tolerance, and surface roughness Ra1.6 or better.

- 3D Printing:

- Resin parts: ±0.2mm

- Nylon parts: ±0.3mm

- Plastic parts: ±0.3mm

- Metal parts: ±0.3mm

Q7: What materials do you support?✅ CNC Machining:

- Aluminum Alloy: 6061, 7075

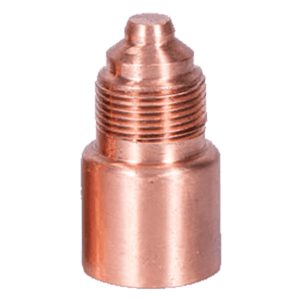

- Copper Alloy: Brass (H59), Red Copper (T2)

- Alloy Steel: 45# Steel

- Stainless Steel: SUS304

- Plastics:

- ABS (White, Black)

- POM (White, Black)

- Bakelite (Black, Orange)

- Acrylic (Transparent)

- FR4 Epoxy Board (Green)

- PA6 Nylon (White)

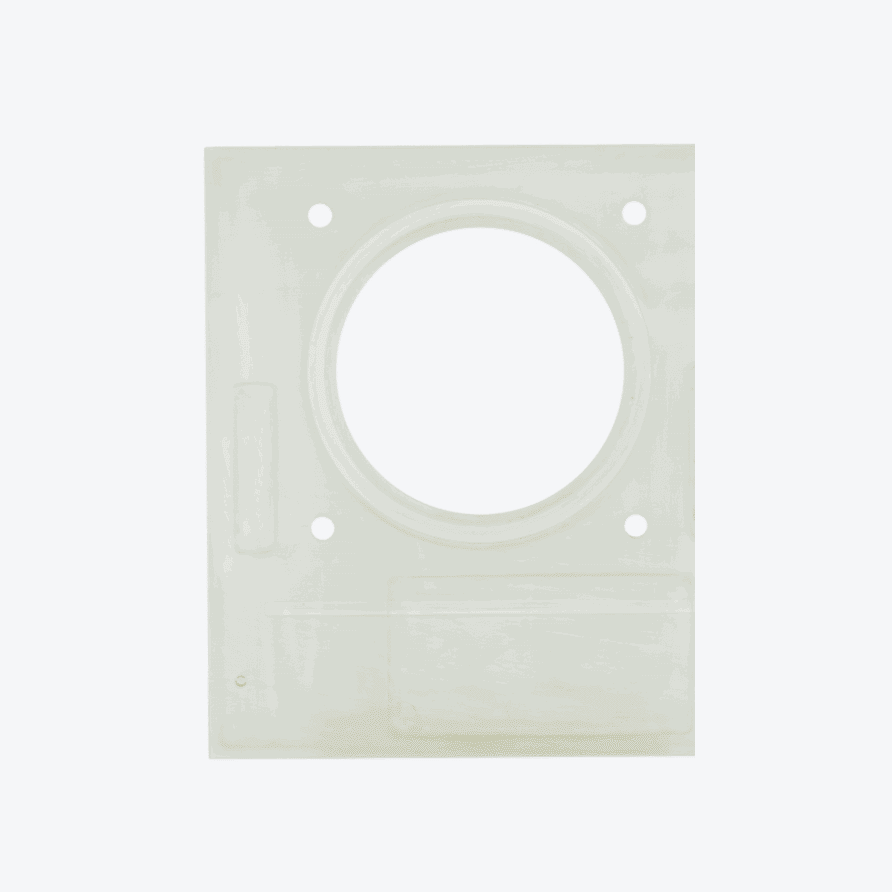

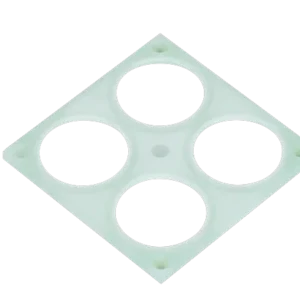

- Polycarbonate (Transparent)

✅ 3D Printing:

- Resin, Nylon, Engineering Plastics, Stainless Steel

After-Sales Service

Q8: What if the parts do not meet the requirements?A: If defects occur due to our processing issues, we guarantee free remanufacturing.