Polyoxymethylene, commonly abbreviated as POM-C, is a polymer derived from the polymerization of formaldehyde. This polymer typically exhibits a low degree of polymerization and is prone to thermal depolymerization. In 1955, DuPont successfully produced formaldehyde homopolymer through formaldehyde polymerization. POM-C is characterized by its high crystallinity, often exceeding 70%, with a melting temperature of approximately 180°C.

Mechanical Properties

Density: 1.45 g/cm³

Volume Resistance (VDE0303): ≥ 10¹⁵ Ω·cm

Water Absorption: 0.8%

Surface Resistance (VDE0303): ≥ 10¹³ Ω

Dielectric Constant (1 MHz, DIN53483): 3.8

Continuous Use Temperature: -50 to 90°C

Dielectric Loss Factor (1 MHz, DIN53483): 0.005

Yield Tensile Strength: 62 MPa

Dielectric Strength (VDE0303): 85 kV/mm

Yield Tensile Strain: 10%

Ultimate Tensile Strength: Not specified

Ultimate Tensile Strain: 40%

Impact Toughness: 0.8 kJ/m²

Notched Impact Toughness: 7 kJ/m²

Rockwell Ball Hardness: 135 MPa

Shore D Hardness: 85

Flexural Strength: Not specified

Modulus of Elasticity: 2600 MPa

Vicat Softening Temperature: 150°C

Thermal Conductivity (20°C): 0.31 W/(m·K)

Chemical Resistance

Acid Resistance: Good

Alkali Resistance: Good

Resistance to Aromatic Compounds: Moderate

Ketone Resistance: Moderate

Carbonic Acid Resistance: Moderate

Thermal Water Resistance: Moderate

Heat Treatment

Drying Treatment: Generally not required if stored in a dry environment.

Melting Temperature: 190–230°C for homopolymer; 190–210°C for copolymer.

Mold Temperature: 80–105°C, with higher temperatures reducing shrinkage.

Injection Pressure: 700–1200 bar.

Injection Speed: Medium speed is preferred; too slow may cause ripples, too fast may cause shot lines and shear overheating.

Runners and Gates: Any type can be used; shorter tunnel-shaped gates are recommended for homopolymer materials.

Back Pressure: Keep low, generally no more than 200 bar.

Retention Time: For POM-H, retain at 215°C for 35 minutes; for POM-K, retain at 205°C for 20 minutes without serious decomposition. POM-K can stay in the barrel for 7 minutes at 240°C; if the machine stops, reduce the barrel temperature to 150°C.

Shutdown and Cleaning

Shutdown Procedure: Clean the barrel with PE or PP, turn off electric heat, and push the screw to the front position. Ensure the barrel and screw remain clean to avoid contamination, which can affect the stability of POM (especially POM-H). If using halogen-containing or acidic polymers, clean with PE before processing POM to prevent explosions. Improper pigments or materials containing GF nylon can lead to degradation.

Post-Treatment

For parts requiring high temperature resistance and quality, perform heat treatment. Annealing can be checked by immersing the product in a 30% hydrochloric acid solution for 30 minutes to identify any residual stress cracks visually.

Order Process

Q1: How to submit a processing request?A: You can contact us via WhatsApp: +86 15323729231 or email [email protected].B: We support STEP/STL/IGES file formats. You can also send your files to our service email. Our system will generate a quote and process recommendations within 1 hour.

Q2: Do you provide design optimization suggestions?A: Yes! Our engineering team offers a free DFM (Design for Manufacturability) review, providing optimization suggestions to improve structure and reduce costs.

Pricing & Delivery

Q3: What is the Minimum Order Quantity (MOQ)?A: No MOQ! We accept orders starting from 1 piece, whether for 3D printing or CNC machining.

Q4: What is included in the quotation?A: The quote covers material costs, processing fees, and basic surface treatment (e.g., sandblasting). Additional processes (e.g., electroplating, anodizing) will be quoted separately.

Q5: What is the standard lead time?

- CNC Machining: 3-5 days (up to 7 days for complex parts)

- 3D Printing: 72 hours

Technology & Quality

Q6: What is the machining accuracy?

- CNC Machining: Fast prototyping with a ±0.05mm tolerance, 0.1mm form tolerance, and surface roughness Ra1.6 or better.

- 3D Printing:

- Resin parts: ±0.2mm

- Nylon parts: ±0.3mm

- Plastic parts: ±0.3mm

- Metal parts: ±0.3mm

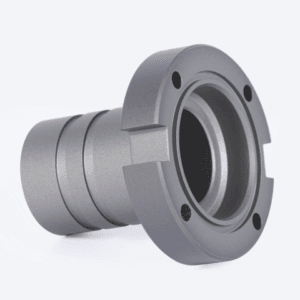

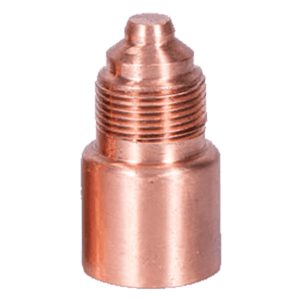

Q7: What materials do you support?✅ CNC Machining:

- Aluminum Alloy: 6061, 7075

- Copper Alloy: Brass (H59), Red Copper (T2)

- Alloy Steel: 45# Steel

- Stainless Steel: SUS304

- Plastics:

- ABS (White, Black)

- POM (White, Black)

- Bakelite (Black, Orange)

- Acrylic (Transparent)

- FR4 Epoxy Board (Green)

- PA6 Nylon (White)

- Polycarbonate (Transparent)

✅ 3D Printing:

- Resin, Nylon, Engineering Plastics, Stainless Steel

After-Sales Service

Q8: What if the parts do not meet the requirements?A: If defects occur due to our processing issues, we guarantee free remanufacturing.