Сторонний фрезерование

Available Materials for CNC Milling

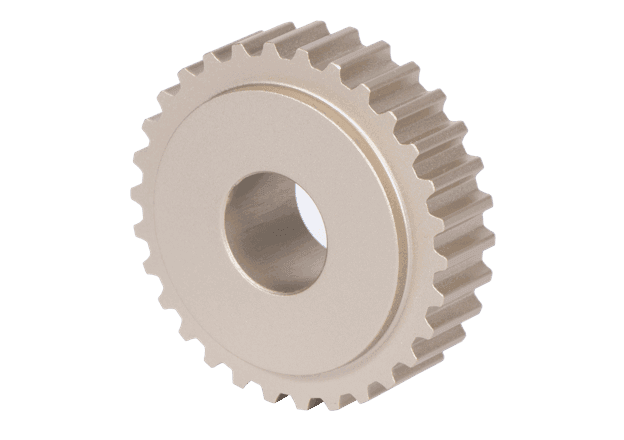

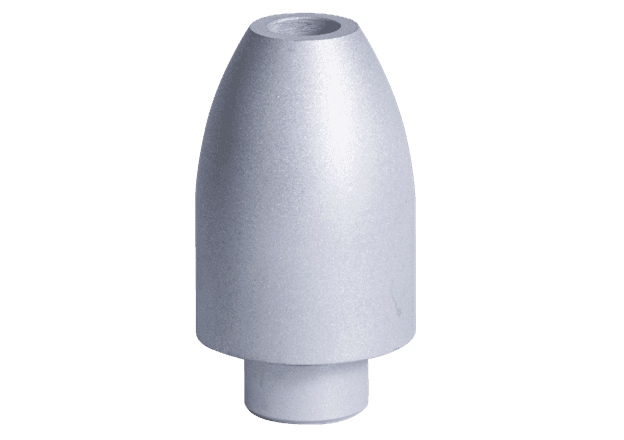

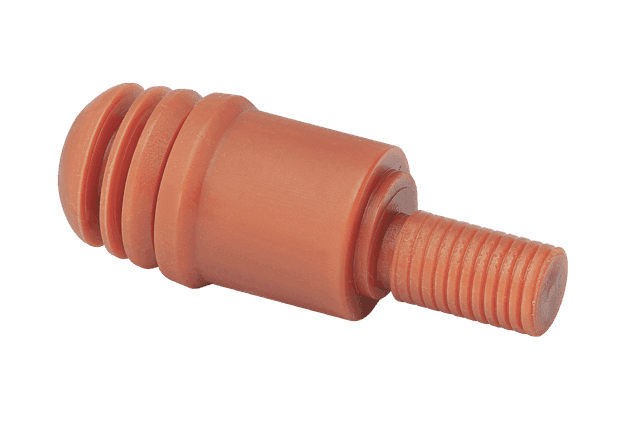

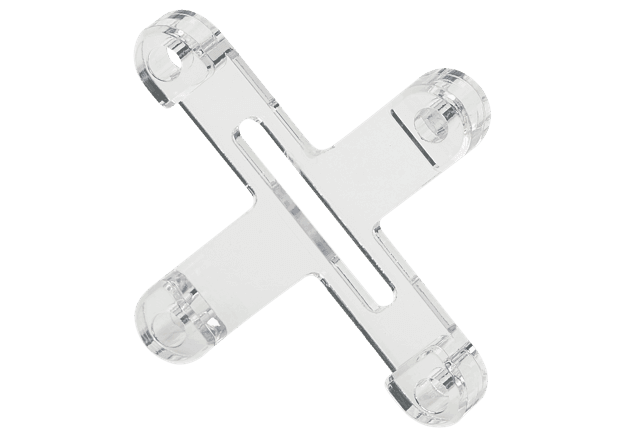

CNC milling is compatible with a wide range of materials, including metals (Алюминий, Steel, Латунь, Медь), пластмассы (Акрил, Нейлон, АБС), composites (Carbon Fiber, Fiberglass), and foams. The choice of material depends on its machinability, which is influenced by factors such as hardness and thermal conductivity. A variety of high-quality materials are available to meet diverse application needs in precision CNC milling.

CNC milling design guidelines

Max Build Size (5-Axis) | 270*260*230мм |

Минимальный размер сборки (3-Axis) | 5*5*1мм |

Минимальный размер сборки (5-Axis) | 5*5*1мм |

Recommend Size (3-Axis) | 5-800мм |

Recommend Size (5-Axis) | 5-250мм |

Min.Accuracy (3-Axis & 5-Axis) | ±0.02mm |

Recommend Accuracy (3-Axis & 5-Axis) | ±0.05mm |

Max Build Size (3-Axis) | 800*600*400мм |

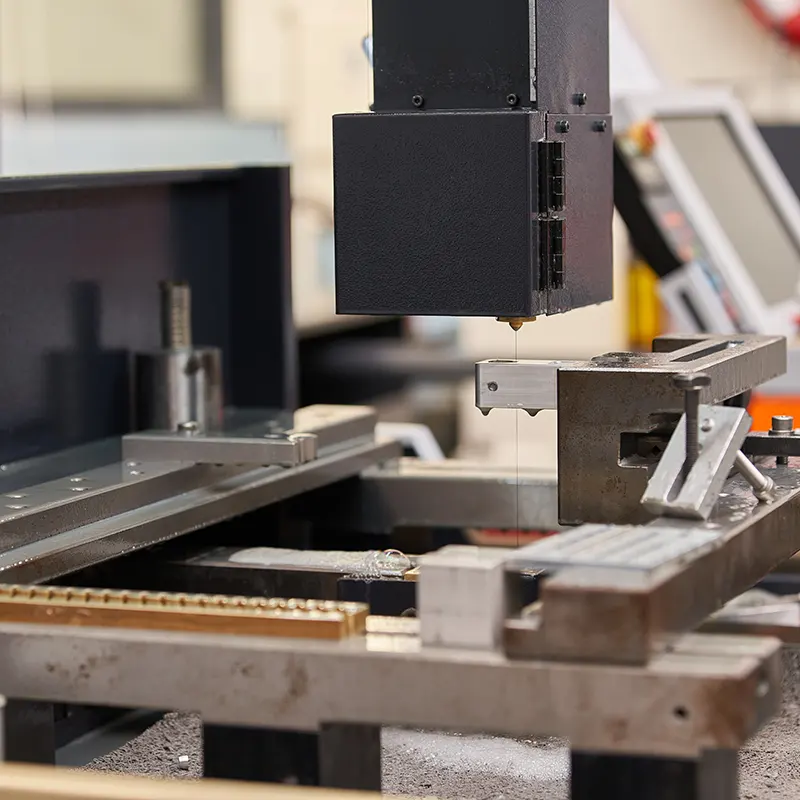

How Does CNC Milling Machine work

A CNC milling machine is a computer-driven tool that utilizes a rotating cutter to precisely remove material from a workpiece, enabling intricate and accurate machining operations. Renowned for its precision, repeatability, and efficiency, it is widely used in manufacturing to consistently produce high-quality components.