Эдм(Электроэрозионная обработка)

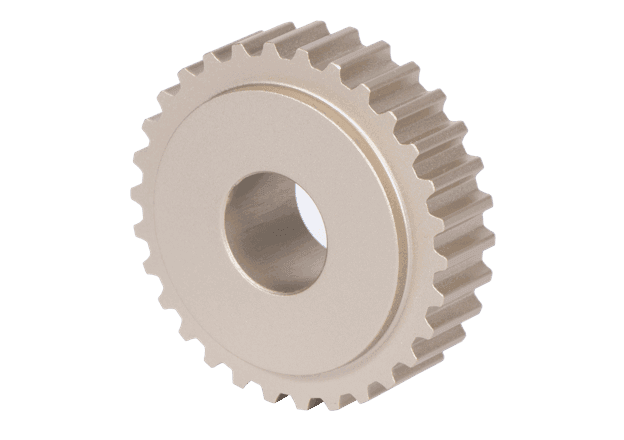

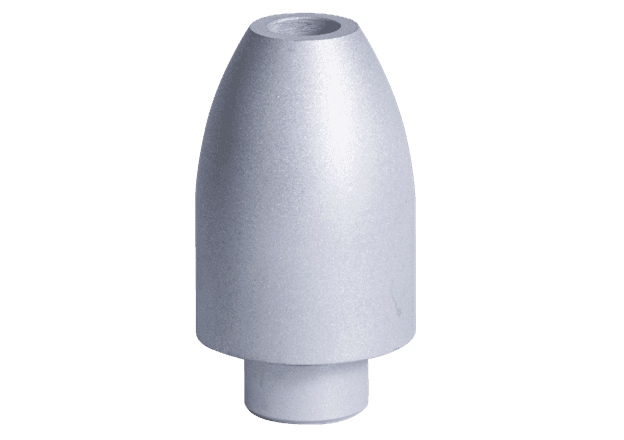

Электроэрозионная обработка (Эдм) is a precision manufacturing process that removes material from a workpiece using controlled electrical sparks, allowing for the creation of intricate shapes and fine details with high accuracy.

Materials suitable for EDM

Эдм (Электроэрозионная обработка) is ideal for working with conductive materials, including metals and alloys such as steel, titanium, медь, tungsten carbide, and graphite. Since the process relies on electrical discharge to erode material, the workpiece must be electrically conductive. A variety of high-quality materials are available to support precision EDM applications.

EDM Design Guidelines

Max Build Size (Conventional EDM) | 400*300*300мм |

Max Build Size (Wire EDM) | 300*300*400мм |

Минимальный размер сборки (Conventional & Wire EDM) | Ø0.5 |

Recommend Size (Conventional & Wire EDM) | ±0,01 мм |

Recommend Accuracy (Conventional & Wire EDM) | ±0.05mm |

How Does EDM machine work

An EDM (Электроэрозионная обработка) machine operates by generating electrical sparks that erode material from a conductive workpiece, usually submerged in dielectric fluid. This process enables the precise machining of complex shapes and hard materials, making it ideal for applications requiring high accuracy and intricate details.